Cutting tools are the unsung heroes behind numerous industrial processes, revolutionizing manufacturing, construction, and various other sectors. From crafting intricate designs to shaping robust materials, these tools play a pivotal role in diverse applications.

1. What are Cutting Tools, and How Do They Work?

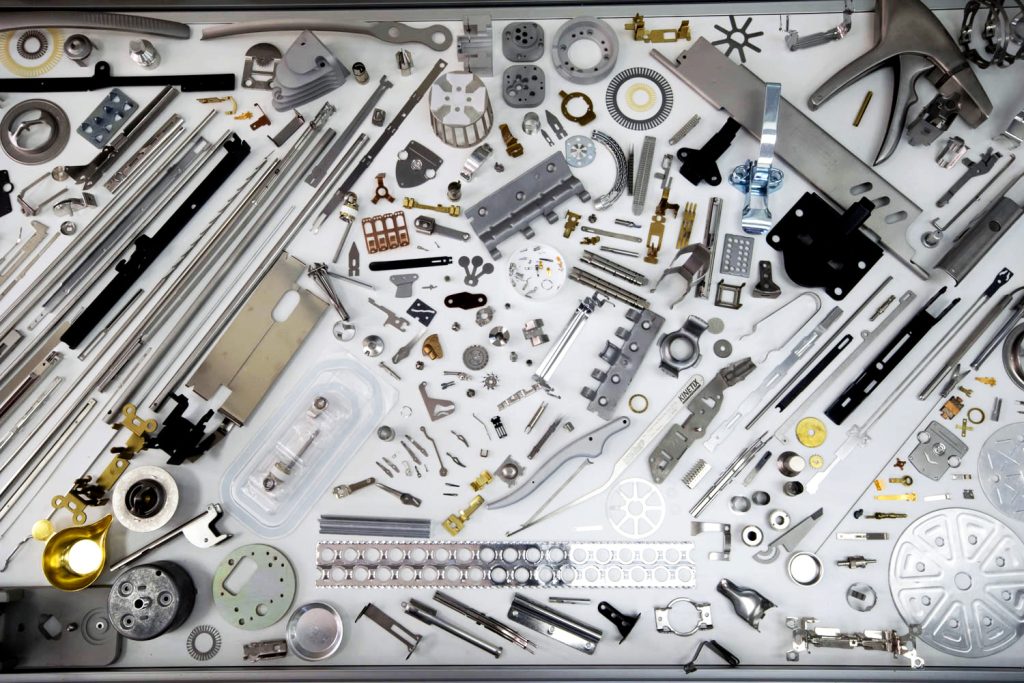

- Definition: Cutting tools encompass a range of instruments designed to shear, slice, or remove materials, from metals to composites.

- Function: These tools operate through a variety of mechanisms, such as abrasion, shearing, or chip formation, to precisely manipulate materials.

2. What Types of Cutting Tools Exist, and Where are They Used?

- Types: Cutting tools span a wide spectrum, including drills, saws, milling machines, and lathe tools, each serving unique purposes.

- Applications: They find applications across industries like manufacturing, construction, automotive, aerospace, and more. For instance, in construction, saws and drills are fundamental for shaping concrete, while in manufacturing, milling machines craft intricate components with precision.

3. How Does Optimization of Cutting Tools Impact Efficiency?

- Optimization: Proper tool selection, maintenance, and use significantly enhance efficiency, reducing material waste and production time.

- Parameters: Factors like material compatibility, cutting speed, tool geometry, and cooling mechanisms influence optimization.

4. Can Cutting Tools Enhance Geogrid Applications?

- Geogrid Integration: Geogrid, a geosynthetic material used in civil engineering for soil stabilization, benefits from cutting tools during installation and shaping processes.

- Relevance: Tools like saws and drills aid in cutting geogrid materials to precise dimensions, facilitating seamless integration into construction projects.

Applications and Geogrid Mention:

Cutting tools hold immense significance in the realm of geotechnical engineering, especially when integrating geogrid materials. Geogrid, a crucial component in reinforcing soil structures, relies on precise cutting and shaping for optimal performance. Tools such as saws and drilling machines ensure accurate cutting of geogrid materials, allowing for seamless incorporation into construction projects.

Moreover, in various industries, cutting tools bolster efficiency and precision. For instance, in manufacturing, CNC milling machines carve intricate designs with unmatched accuracy, while in construction, diamond-tipped saws effortlessly slice through tough materials like concrete and asphalt.

In essence, the synergy between cutting tools and geogrid illustrates the versatility and importance of these instruments across diverse sectors. Their role in enhancing productivity, precision, and material utilization cannot be overstated.

As industries continue to evolve, innovations in cutting tool technology will undoubtedly drive advancements, further elevating efficiency and expanding possibilities across multiple domains.