How many machinists know a good file when they see it? I don’t believe one in fifty can take a pile of files and pick out the best one. The average man will pick up two or three, turn them over, squint along the corners, pick out the straightest one and call it as “good as any.” They don’t seem to have any idea that a file may be soft, or fire-cracked, or burned. If they were choosing a cold chisel they would look out for all these things, but “a file is a file” so long as it has teeth and tang.

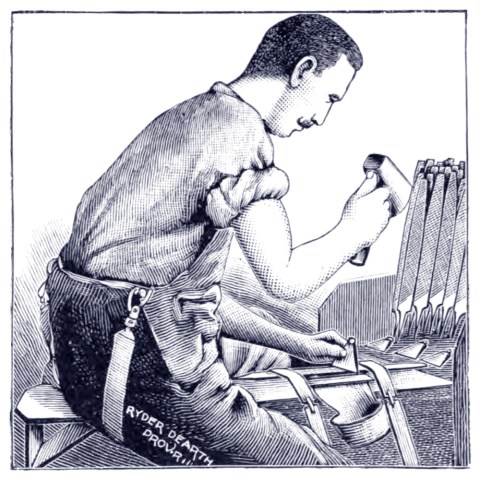

Talk about certain tools being abused in the machine shop, or in any other shop. What is more abused than a file? No matter what job is on hand, they are expected to take right hold of it and never let go. Hard iron, soft iron, steel or lead, brass, copper or wood, it makes no difference. The file must go at it hammer and tongs.

If the job is covered with an eighth of an inch of grease and dirt, it is all the same. The workman uses one corner of the file to scrape off part of it. When he gets the file well filled with oil he tries to wipe it off on a piece of dirty waste, or the leg of his overalls. He succeeds in filling up the remainder of his file, rather than in cleaning it.

If the job is covered with a generous coat of rust, what matter; the file must scrape it off, and then before it would be half worn out by proper usage, it is pitched into a corner, or dumped into a load of lathe chips, and our chap, if he is in a country shop, watches his chance to “cabbage” a new file.

Shops having tool rooms where a man is required to return the old file in order to draw a new one, ought to fare better, but they don’t—not much. If Dan or Jim can’t find ways and means enough to soft-soap or fool the tool-room chap, then they aren’t like ordinary machinists, and had better complete their education.

But to choose a good file, just hold it between your eye and the light, point toward you; you can see the cutting edge of every tooth. See if they are all clean, smooth, and sharp. If they are notched, cracked, uneven and irregular, then they belong to a poor file.

Take a directory and find out who makes files. If you find a file with a man’s name upon it, who is really making files, then that file is one of his first quality. Seconds and thirds have fancy names stamped on them. It don’t pay to buy them.

Fourth class files are left without stamping at all, or rather it is not re-stamped with any fancy name. All files are stamped before tempering, but if damaged in any way, the name is ground off, and re-stamped or left blank according to grade.

Look a file all over for fire cracks; hold up to your eye as before, put the point toward the light, and see if it is all one color. If it shows a checkered appearance, it is uneven in temper, hard and soft in spots. Toss the file into the air and strike it with the handle of your pocket-knife, or some other hard substance. If there are any flaws in that file, the ring of the steel will give them away.

Buy large files; they stand recutting better than thin ones. There is not much choice, however, for within the last two years file makers have established a uniform size and weight for the same class of files.

Machine-cut files are not liked very well by some; it is claimed that they will not do as much work as the hand-cut, but I have used machine-cut files, and didn’t know it until afterwards. Somebody is going to make a machine that will cut files better than hand labor can do it. Does it stand to reason that files cannot live in the age of machinery, when almost everything else lives and dies by machinery and is buried in a machine-made coffin, or burned in a cremating machine?

A poor file is not worth a “continental;” they amount to about as much as Fink’s lubricator. I remember one chap that came along with a nice looking lot of files. He sold a lot to nearly every shop in town. He sold them “cheap”—he said—but when the boys came to use the files, the cat tumbled out of the bag, and that “agent” was wanted by the boss.

The files were nothing but poor iron. They were treated with prussiate of potash, and came out case hardened a little, and looking nice and clean. I always think of that dodge when I see a man selling a “job lot” of files. Don’t buy low-priced files, thinking them cheap; that is unless your men make scrapers of them as described. If that is what you want them for, the case hardened ones are just as good as any.

I once made a rule which I have never since broken. When I got a new file I always fitted it with a handle before using. Just try this once, and you will always stick to it. The machinist has, of all men, no excuse for not having handles to his files. Nearly every shop in the United States has a speed lathe connected with it, and handles may be had for the making.

If I were bossing a shop, files would be fitted with handles before they left the tool room. If a man can’t get at a speed lathe, let him knock out the live center on his engine lathe, whittle down the end of a pine stick and drive it into the spindle, bring the tail spindle up to it and turn out a handle with a hand-tool.

I remember one old chap in a little country shop, who used to go out to the grist mill which was connected with the same water power, and get corn cobs for file handles. He would cut off about three inches of the butt end, drive the tang into the pith, and had a handle at once.

I want wooden handles on my files, and ferules on the handles. In almost every shop a piece of brass tubing is to be got hold of, and you can cut off ferules to order. Sometimes I have been driven to make my own ferules. A piece of sheet or hoop iron was cut the right size, rolled up and brazed together. Any “cub” who had been around the shop six weeks used to know how such a job was done, but now lots of jours never even saw it done.

Put a little powdered borax in the ferule, with a small piece of soft yellow brass, or brass filings. Hang it on the end of a poker, and heat in the forge until the brass melts; heat gradually, or you may burn the iron as well as melt the brass. Just as quick as the brass melts, it will be known by the blue flame. Remove from the fire, cool, and file off superfluous brass. You can finish in the lathe with an old file after it is fitted to the handle.

Don’t try to get along with three or four handles. Make a handle for each file, and keep them on them. If Tom or Mike wants to borrow a handle “just a minute,” send him to the lathe where you made yours and tell him to help himself.

Use a file as well as you do your steel square or straight edge. You would think a man was foolish or crazy if he threw these tools ker-bang into a drawer when he was done with them; but the files go in just like that. Corners are dulled, teeth knocked off, often the file itself is broken. Drop a flat file two feet upon a bench; if it strikes square it breaks every time. I have seen one break into four or five pieces.

If a file gets full of grease, put it in a kettle with potash and water, boil an hour, then wash and brush in clean water, dry, and rub on a little oil. “Almost makes a new file of it,” said Dan, as he picked it up and looked it over. Dipping files in sulphuric acid and water seems to sharpen up dull teeth a little. The acid eats off the steel and leaves the tooth sharper. Lay a file away six months, and, if it is decently clean the oxygen of the atmosphere eats up the steel in the same manner as the oxygen of the sulphuric acid and water.

These ways, however, don’t amount to much. Better let the file-man take your old files and re-cut them. It costs about one-third the price of new files. Some files will stand re-cutting two or three times; these were made from good stock. I have seen them as thin as an “Arkansas hog,” but cut as well as when new. If the file has been overheated, it never will pay to re-cut it; drop it into the old iron and charge to profit and loss.

Once in a while a file will got broken, even with the best of care; but, with the knocking about they are subject to it is a mystery how any of them come out whole. Tell the boys to bring a file to you the very minute they break it. Don’t swear over it; it don’t help the file any, and that chap won’t bring one the next time he breaks it.

Have a little bottle of muriate of zinc (zinc dissolved in muriatic acid), and wet the break with it immediately; then heat a soldering iron and tin the ends of the file. Heat the file pretty warm—not enough to start the temper, but rather too hot to hold in the hand. When well tinned and hot, press the two pieces firmly together, squeeze out nearly all the solder, and let the file cool. Trim off the joint, and, if well done, the file will break in another place the next time.

It will not pay to solder a file unless it is nearly new. Let it lay a day or two, and you never can mend it so it will stay. Take it the minute it snaps, and you can do what they used to stick a ‘prentice on, viz. mend a file.

If you are acquainted with a file-maker, you can sometimes get “damaged” files at a discount. When the damage is caused by tip ends breaking off, etc., it may pay to buy them; but, like a steam engine, it pays to buy the best that is to be had, and, as in the case of the steam engine, it takes a smart man to tell which one that is.

James F. Hobart

American Machinist – January 10, 1885

—Jeff Burks