Wrenches serve as essential tools in the world of mechanics, providing a versatile solution for tightening and loosening nuts, bolts, and threaded parts. Their varied shapes and sizes cater to a wide range of needs, from minor household repairs to heavy-duty industrial applications. This guide navigates through the realm of wrenches, examining their applications, functionalities, and their role within geocomposite manufacturing.

What are the different types of wrenches available and their specific uses?

Wrenches encompass various types, each tailored for specific tasks. Adjustable wrenches offer versatility with an adjustable jaw, suitable for multiple bolt sizes. Socket wrenches employ sockets of different sizes, ideal for handling bolts in cramped spaces. Combination wrenches combine an open-end and a box-end, while torque wrenches ensure precise tightening with predetermined torque levels.

What are the primary applications of wrenches?

Wrenches serve diverse industries and purposes, from automotive repair shops to construction sites and household maintenance. In manufacturing, they play a critical role in machinery assembly, while in plumbing, they assist in fixing and maintaining pipelines. Additionally, wrenches are indispensable in assembling and maintaining various mechanical systems across industries.

How do wrenches contribute to the geocomposite manufacturing process?

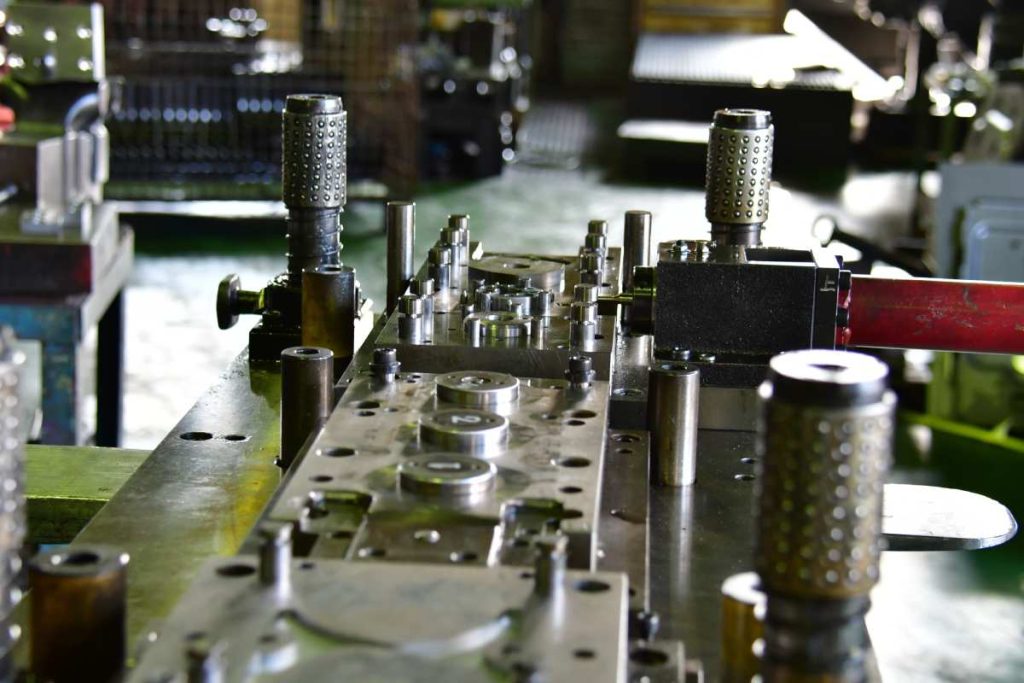

Geocomposites, extensively used in civil engineering for soil stabilization, drainage, and environmental protection, demand precise assembly. Wrenches contribute significantly to geocomposite manufacturing by aiding in machinery assembly and ensuring proper alignment and tightness of components.

What are some best practices for using wrenches safely and effectively?

For safe and effective usage, selecting the right wrench for the task is crucial. Always use the correct size and type to prevent damage to both the wrench and the fastener. Before use, inspect the wrench for damage or wear, apply force steadily, and ensure proper positioning to prevent slippage and reduce the risk of injury or damage to the fastening mechanism.

Applications and Geocomposite Relevance:

Aside from their traditional applications in automotive, construction, and household maintenance, wrenches play a significant role in geocomposite manufacturing. These composite materials necessitate precise machinery assembly, and wrenches guarantee accuracy, ensuring the quality and efficiency of geocomposite manufacturing equipment.

In conclusion, wrenches stand as indispensable tools, offering versatility and reliability in fastening tasks across multiple sectors. Their involvement in geocomposite manufacturing underscores their importance in specialized industrial applications, contributing notably to infrastructure and environmental engineering.