(Continued from Laying and Finishing Hardwood Floors)

The frequent inquiries in the Correspondence columns of Carpentry and Building indicate that there is a dearth of knowledge as to the proper method of sharpening a scraper. Without any disposition to assume superior knowledge in this connection I am constrained to remember that we cannot clean our floor without sharp tools, and will give your readers the benefit of my experience along this line.

I presume that every reader understands that the cutting edge of the scraper is formed by turning over a “burr” or wire edge, which does the cutting when applied to the wood. This burr is made by rubbing against the edge of the scraper with a tool called a burnisher, which may be made of any piece of steel of convenient form but which must be harder than the scraper.

A common method is to grind a file down until a perfectly smooth surface is secured with the corners slightly rounded and the tool set in a convenient handle. A simpler and much better method is to grind a smooth point on a discarded nail set and mount it in a handle, like the burnisher illustrated. Do not forget to put a point on it and make it sharp.

Whether the edge of your scraper should be square or beveled will depend on the class of work you have to do. If it is fine bench work on very hard wood and you wish the finest possible finish use a square edge and turn the burr on your scraper for a light shaving. If you are on a floor or other work where fast cutting is required and plenty of sandpaper will follow use a beveled edge and have plenty of steel back of the edge to hold it firm.

Whether you file or grind your scraper will depend largely on the temper of your steel and your own disposition. In either case you will have to whet the edge smooth on an oil stone before a satisfactory cutting edge can be obtained. Now don’t forget that to have a scraper cut well it must have an edge as smooth as any other edged tool used for fine work and this edge can only be obtained on the oil stone.

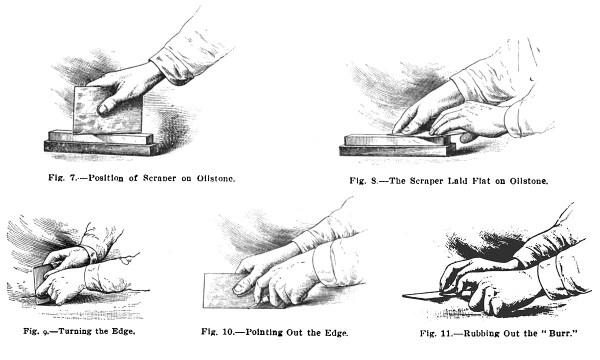

If you are using the common cabinet scraper and the class of work will permit, the square edge will be desirable, inasmuch as you can secure eight cutting edges and avoid frequent sharpening. Let us suppose that we have ground or filed a straight and smooth edge on our scraper, then put it on the oil stone. After you have rubbed down a pretty smooth edge turn the scraper down flatwise on the stone and take off the wire edge.

Repeat these operations with every cutting face of your scraper until you have a corner as smooth and sharp as you would put on a smooth plane. Having reached this point we are ready for the burnisher. Now set your scraper firmly on the bench and hold it in position with your sinister hand while the dexter one grips the burnisher and with a stout upward pull against the corner turn the edge. Better protect that sinister hand with a bunch of shavings or something else, for the edge is likely to cut your hand if the oil stone has done its duty.

You will now find that there is a little hooked edge turned over on your scraper if you have made a hard and steady pull with the burnisher. To make sure that this edge will be perfectly smooth turn the scraper down on the bench at an angle and “point out the edge.”

Here is where that sharp point comes handy on the burnisher. Incidentally, it is useful for starting screws, marking keyholes, in fitting locks, &c., but indispensable as a sharpener for the scraper. Be careful to put the point exactly in the angle where the little burr turns over the edge of the scraper and ever so lightly and carefully draw it along the whole length of the angle to smooth up the cutting edge of the burr, then more lightly than at first turn the edge again with a single stroke of the burnisher.

If you have been happy in following these poor instructions you will now have an edge which will cut a shaving as fine as silk and as fast as you can pull the tool. Presently it will get dull. This will be largely caused by the gathering of fine particles of dust in the angle of the burr if your wood be free from sand or grit, so take your burnisher and carefully “point out” again and turn the edge lightly afterward. You will be surprised, if not familiar with this method, to see how long the tool holds its edge without sharpening, but don’t forget that everything depends on the oil stone to begin with.

After this operation has been repeated two or three times the scraper will really become dull and the pointing out process fail to work. Then turn the tool flat down on the bench and with the burnisher rub the edge smooth. A few brisk strokes of the burnisher will turn back the burr and the edge will be observed to be more or less full of imperfections. If not too badly worn and the steel be of good temper you may return to the oil stone and again smooth up the edge and repeat the processes of turning, pointing out and finally turning the cutting edge.

Having our tools all well in order and possibly a trifle in advance of the time of need we will proceed to the preparation and laying of the floor…

Frank G. Odell.

Carpentry and Building – January, 1906

The complete text was published under the title “Laying and Finishing Hardwood Floors” by Frank G. Odell – The David Williams Company 1906.

—Jeff Burks